Machine Safety vs. Machine Guarding: Is There a Difference?

Welcome back to another Spotlight on Safety! Today we’ll be answering the above question: what is the difference between machine safety and machine guarding? Well, they’re not so much different, as they are complementary.

Machine guarding is just ONE facet of overall machine safety! Machine safety encompasses any training, repetitive action, signage, safety restrictions or restraints, personal protective equipment (PPE), and anything else that protects workers from injury when they interact with machinery.

So how can you make sure you’re doing enough to keep your employees safe while they work with machines? There are several steps you can take!

TRAINING

Here at Folding Guard, our employees are trained individually on every single machine they’ll need to use for work. The employee never operates the machine alone until his or her trainer and our safety team is satisfied that they are completely knowledgeable about the machine and its operation and safety standards. Never let an employee work with a machine that they don’t seem comfortable using. A properly trained employee is a safe employee.

PPE (Personal Protective Equipment)

Machines are made up of moving parts, and the humans who interact with those machines are, well, only human. Therefore, it’s important that every possible precaution is taken to protect your employees from mechanical glitches and human error, in an effort to prevent injury.

Machines are made up of moving parts, and the humans who interact with those machines are, well, only human. Therefore, it’s important that every possible precaution is taken to protect your employees from mechanical glitches and human error, in an effort to prevent injury.

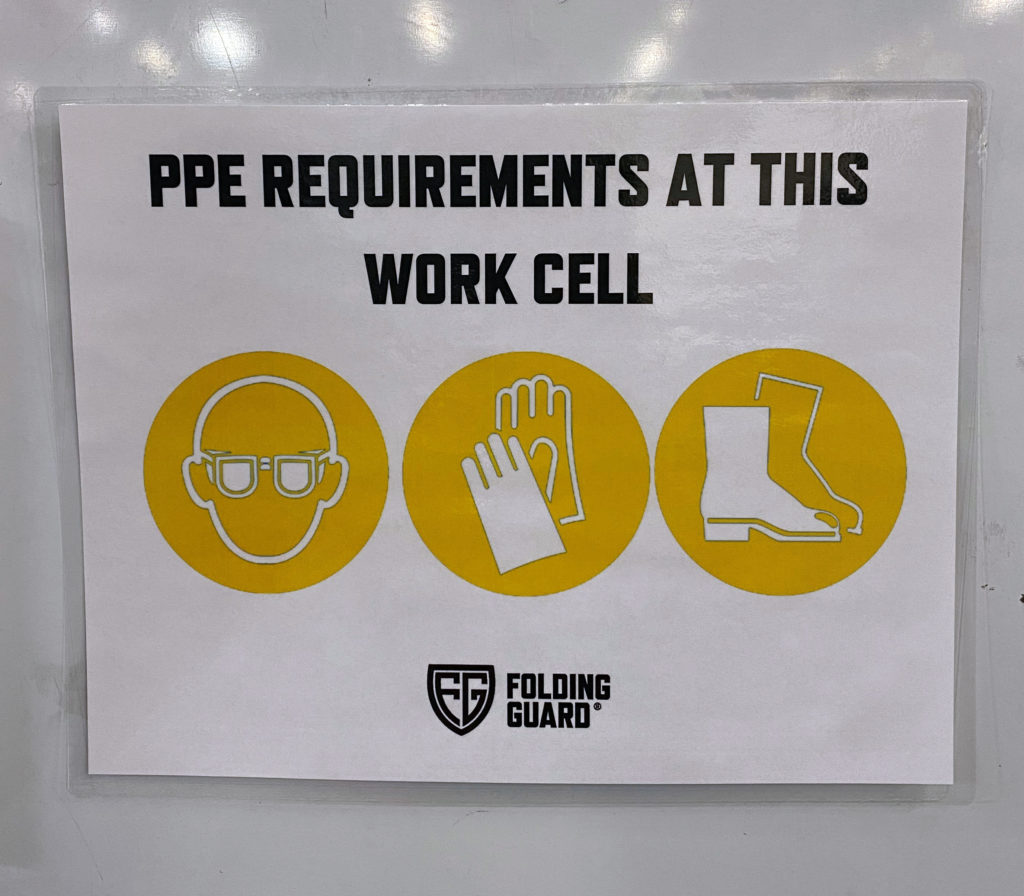

PPE is the first line of defense between employee and machine. Make sure your PPE is properly maintained, and replace anything that is old or faulty immediately. Different machines require different protection, so make sure to impress upon your employees which PPE to use during their training. To learn more about the importance of PPE, check out our PPE Spotlight on Safety!

SIGNAGE

Manufacturing facilities and plant floors are busy, noisy, and often full of distractions. To make sure your employees and even visitors to your facility are safe around machines, it’s important to post proper signage warning people of potential hazards.

If your employees are multilingual, make sure your signs are posted in every language represented by your workforce; even the smallest misunderstood detail or word could result in an injury. Making your signage multilingual will ensure that every employee understands and protects themselves against the hazards of the machines they’re working with.

It’s also helpful to post graphic signs, especially where PPE is concerned. When employees are familiar with the graphics representing different equipment, they’ll know exactly which PPE to wear around which machines (e.g. goggles, gloves, hardhats, masks, or special footwear).

MACHINE GUARDING

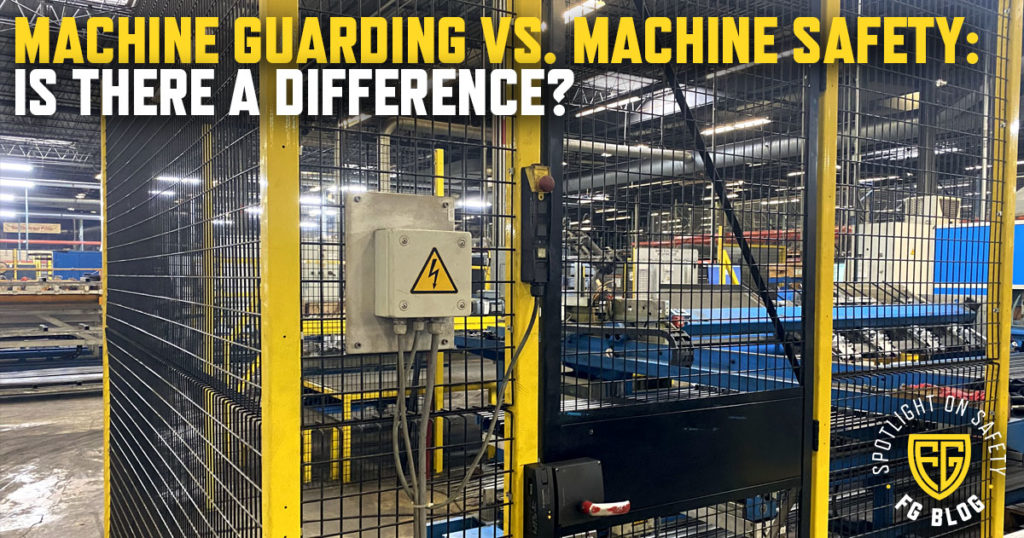

And we’re back to the phrase that often gets confused with overall machine safety. Machine guarding actually refers to a literal physical barrier between the manufacturing floor and a moving machine, designed to prevent workers from coming into contact with hazardous moving parts.

Typically machine guarding is made up of wire mesh, which contains a particular machine within a specified area, and ensures that none of its moving parts can fly out or come into contact with passers-by. The wire mesh is also helpful in that employees can see through it to the potential hazard.

Another safety measure you can add to your machine guarding is a safety switch: a mechanism installed on the door of your machine guarding structure that will send a signal to the machine if the door is opened. This will stop the machine so that it is not in motion while employees are inside the guarded area.

At Folding Guard, we specialize in machine guarding that is versatile enough to be installed around any machine, and with small enough openings in the wire that the fence can be placed closer to the physical machine, taking up less floor space while still preventing wayward fingers from slipping through. FG machine guarding is also compatible with safety switch interlocks. Machine guarding is one the most important investments you can make to keep your employees safe on the floor.

AWARENESS

We’ve written before about the importance that awareness plays in safety, but it can really never be overstated. Employees working with machines must be entirely focused on their work and the machine they’re using so that it doesn’t create a hazard; one distraction or stray thought away from the job could result in serious injury.

Our own Safety Manager, Michael, said it best: “Don’t stick your hands where you’re not supposed to stick your hands and always keep your mind on what’s in front of you.” Employees must be aware of the machine and themselves at all times to maintain safety.

So what IS the difference between machine safety and machine guarding? The difference is that machine guarding, while incredibly important, is only one small step toward creating and maintaining a safe work space around machines. Overall machine safety must be taught and maintained by everyone in order to ensure a truly safe work environment.