Client Collaboration: The Folding Guard Way

Think about the last time you custom ordered something. It might have been anything from a piece of engraved jewelry or custom athletic gear to something as big as a new home. You had a picture in your head of exactly what you wanted.

Was it a nerve-wracking process, waiting to see if it turned out the way you had hoped? Was there a lot of tedious back and forth with the company you ordered from, trying to get the product to match your exact specifications?

When you custom order anything, it’s because you have a specific need, and no one knows better than you how to meet that need.

Customized Orders

At Folding Guard, we get custom orders all the time, and safety, security, and storage solutions do not always fall into the “one size fits all” category. As we mentioned earlier, custom ordering anything, especially anything on a large scale like security fencing for a data center or an entire room of tenant storage lockers, can be a stressful process with a lot of exhausting back and forth.

Here at FG, however, we’ve found a way to make the custom design process a collaborative one, by making our clients members of their very own design dream teams and share ideas between each other.

Typically, when a client orders a custom design from a fencing company for a large or complicated project, they will first tell their sales rep what they’re looking for. The sales rep will pass that along to the design and engineering team. The engineers will create a design draft for the project. They will then give it back to the sales team, who will then present it back to the client.

More often than not, something will get lost in translation throughout that process, and when the client sees the draft, they will have several notes on changes that need to be made. Then the entire process starts again, and repeats several times until both sides are happy with the draft.

Only then does the manufacturing process begin.

Skip the Back-and-Forth and Collaborate

Here at FG, we’ve managed to condense this process by making it a collaborative one. When a client has a large or complicated custom order, they have the opportunity to discuss it with not only their account executive, but with our actual engineering team. That way, the engineering team can create a draft by actually hearing the client’s needs and viewing blueprints and design specs of their space, discussing the drawbacks and benefits of certain choices on the spot.

All of this is done from the get-go, before the client even gets a quote. Rather than charge additional fees for the CAD (or Computer-Aided Design) drawings, here at FG we want you to know what you’re getting before you choose to work with us.

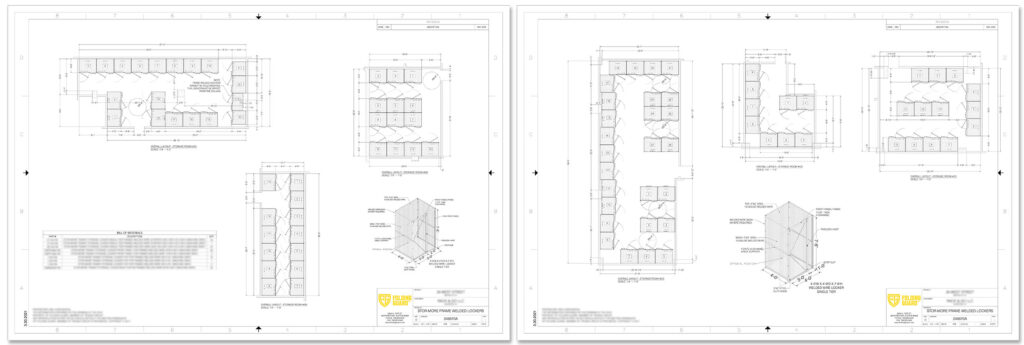

A client can contact our sales team, who can get the engineering team in on the process, and they can all discuss the client’s needs together, which in turn increases productivity and efficiency on the project. Once the CAD drawing is created, along with a bill of materials, the quote is given to the client.

Embrace Virtual Technology

New technology and video conferencing software has streamlined the collaboration process even further.

“By utilizing ‘Zoom’ or ‘Teams’, we can mitigate emailing back and forth by putting the customer’s plan or sketch on screen, and speak directly to the customer’s needs and possible obstructions within the building plan,” our Engineering Manager, Greg Schweinberg, explains. “With the customer, sales team and engineer all on the call, each at their respective locations, time is saved, and miscommunication is eliminated.”

This custom process can be used for any product application: data center security, machine guarding, tenant storage, and more. Take tenant storage, for example. Usually when a client goes to a fencing company to order tenant storage, they might simply order a certain number of lockers and fit as many as possible into their storage room, without really maximizing the space. Oftentimes, clients don’t even realize that they can create larger and more efficient storage spaces with our partitions than with traditional storage lockers.

With our collaborative process, the client can present us with the blueprint of their space and note any specific requirements they have, and our design team can draw up an efficient way to fit the maximum number of storage units, while also accounting for and working around structural obstacles like pipes and pillars.

Quality Products and Relationships

John Caramanna, one of our Regional Sales Managers here at Folding Guard, extolls the benefits of this collaborative process. “The benefit is that you know what you’re getting, you have a detailed plan of what it’s going to look like and what the project’s going to consist of.” By condensing the design process into this collaborative operation with the client, we’re eliminating the tedium, the miscommunication, and the stress that sometimes comes with a custom design.

At Folding Guard, we pride ourselves on our quality products, and more than anything we value our relationships with our clients. This successful collaborative process is a great way for our team and our clients to work together to create the best possible safety, security, and storage solutions to meet each individual need.

Do you need help finding the right safety, security or storage solution for your business? Folding Guard can help! Reach out to your local sales rep today to get started.