What is a Gemba Walk?

For this month’s Spotlight on Safety, we’re going to take a look at a Gemba Walk: an industry practice that isn’t necessarily focused specifically on safety. However, since efficiency and safety go hand in hand, it’s fair to say that Gemba Walks are a very effective way to make your manufacturing facility a safe place to work!

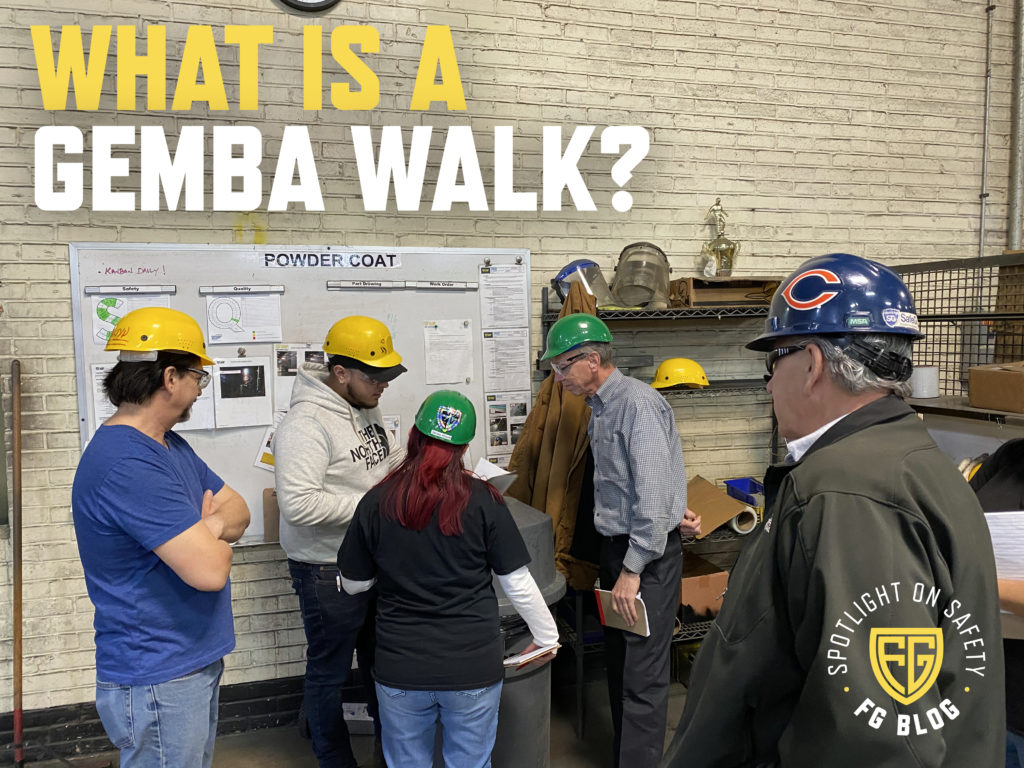

But what IS a Gemba Walk? The word Gemba (sometimes referred to as “genba”) is a Japanese word meaning “the real place.” In business, Gemba is used to refer to “the place where value is created,” and specifically in manufacturing, Gemba refers to the factory floor. A Gemba Walk, specifically, is when a team of managers or executives comes out onto the manufacturing floor, not to scrutinize, but to observe, ask questions, and learn about possible areas of improvement. As we’ve discussed in other Spotlight on Safety articles, a warehouse facility or manufacturing floor is a workplace with multiple potential safety hazards, and the key to preventing these potential hazards from becoming accidents is awareness. A daily Gemba Walk is paramount in building area awareness for supervisors, operators, and even managers in other lines of business in the company.

During a Gemba Walk, managers and executives have the chance to walk the floor and try to truly understand the day-to-day operations of their companies. It’s important, however, that a Gemba Walk have a focus. The Gemba Walk for the day can focus on a particular aspect of the floor, and the managers can ask in-depth questions of the employees in that area in order to better understand the process of their work, rather than just walking the floor and asking questions at random. By having a singular focus for the day, the managers on the Gemba Walk can narrow in on that area and truly understand how it works, and what improvements need to be made.

Gemba Walks are NOT an opportunity to scrutinize employees. If employees feel that they are being micromanaged or set up to be “called out” during a Gemba Walk, they will likely shut down or perform their tasks differently than they normally would. This is completely counterproductive and defeats the purpose of the Walk. When properly done, a Gemba Walk gives management real areas of focus to improve upon and streamline. They can speak to the people who do the actual work and understand the problems that need to be solved. However, if employees feel intimidated or know that they won’t be listened to, the Gemba Walk becomes irrelevant. The Walk is also a chance for the managers to show the workers on the floor that they genuinely care about what is going on. The employees are given a chance to discuss issues while providing real-time examples. The managers can then see how things like missing materials or late machine repairs affect their operation.

Our focus so far has been on how a Gemba Walk should run, and how it can affect efficiency, but how can a Gemba Walk affect safety? When upper level management has a regular presence on the manufacturing floor, they have a better understanding of the processes at work and the potential hazards posed to their employees. By inviting input from these employees during the walk and by seeing the value of that input with their own eyes, management will tend to take ownership and make quicker and more effective changes than they would if a concern was trailed to them in an email. Basically, by being on the floor, being aware of their employees’ workspace, and encouraging and inviting feedback, managers who take Gemba Walks create a safer and more efficient environment for their teams.